from fabric to non-FABRIC.

REGENERATIVE

TECHNOLOGY

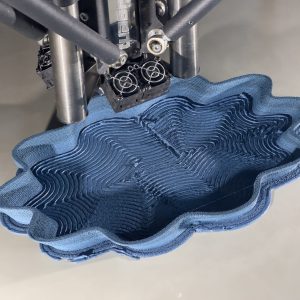

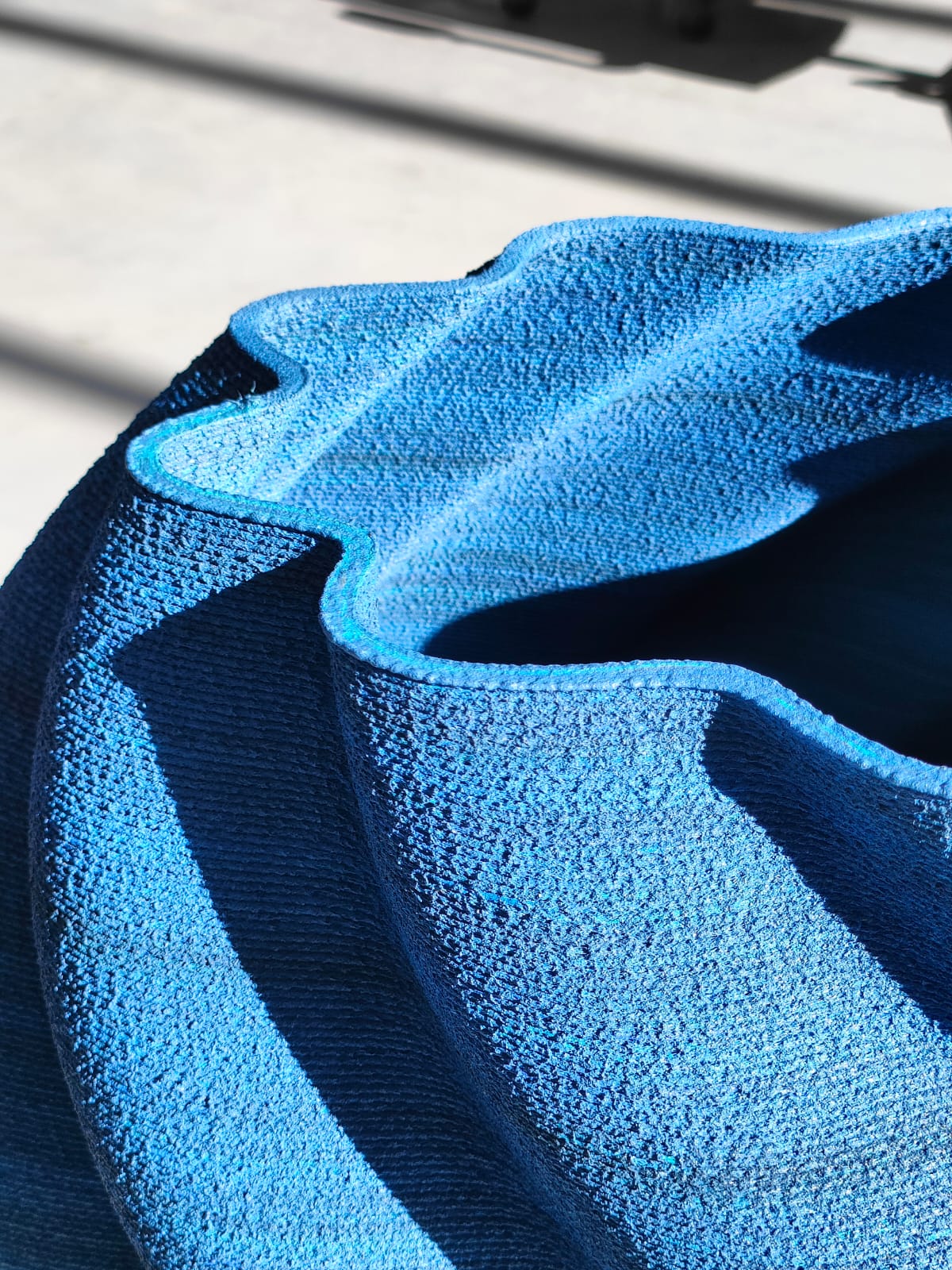

We are an innovative female-led startup and a benefit corporation that transforms civil and industrial textile waste into secondary raw materials through a patented technology unique in the world.

The project was born in 2019 with a clear objective: to become the leading technological solution for transforming industrial and civil waste into secondary raw materials with plastic-like properties.

Regenstech is the result of the insight and experience gained by the founders of Regenesi, a circular-native retail brand and pioneer in green fashion.