BEYOND OVERSHOOT DAY: HOW REGENSTECH REVOLUTIONIZES TEXTILE WASTE REGENERATION

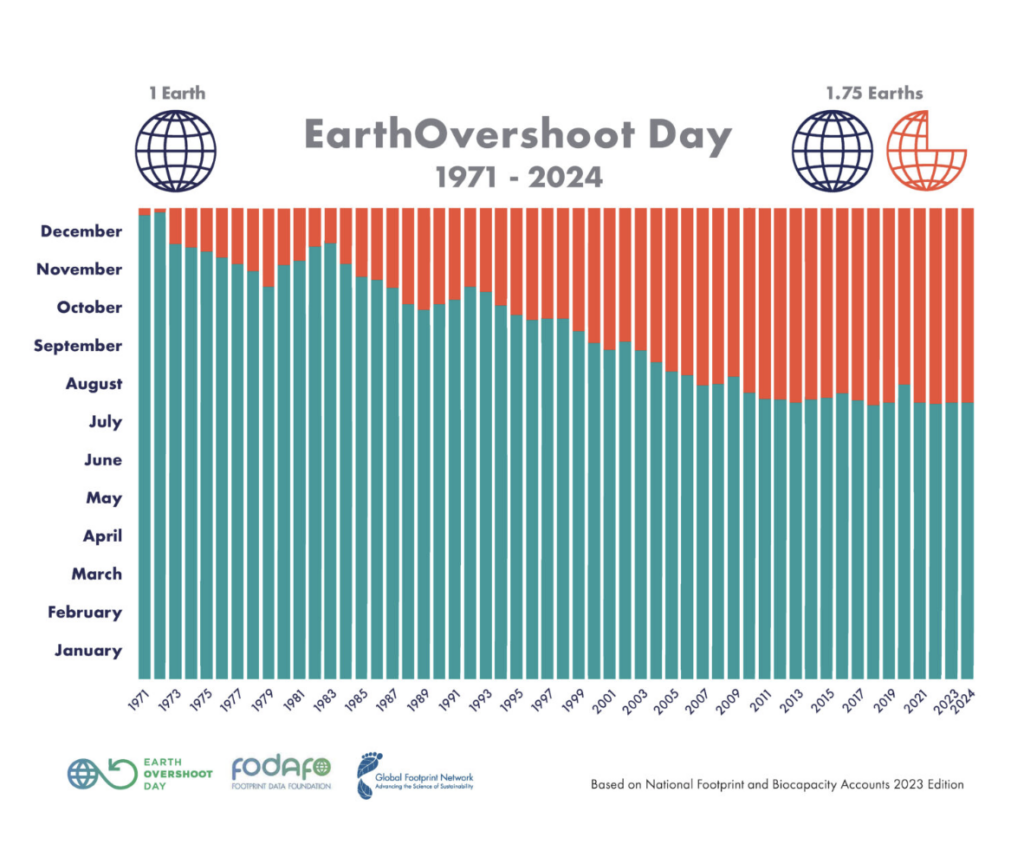

Yesterday, Italy reached a sad record: our national Overshoot Day. This date marks the moment in which we have exhausted all the resources that the planet can regenerate for our country in the whole of 2025. From today, we are living in “ecological debt”, consuming resources that the Earth cannot replenish within the year.

OVERSHOOT DAY: A GROWING DEBT TO THE PLANET

Overshoot Day represents the moment in which human demand for natural resources exceeds the regenerative capacity of the Earth’s ecosystems. In other words, it is the day in which humanity begins to use more natural resources than the planet can renew in a year.

For Italy, this date has become increasingly worrying: while twenty years ago it fell at the end of June, today we have arrived at the very first days of May. A trend, both global and national, that reflects an increasingly unsustainable consumption model and that requires urgent reflections and actions involving both industrial policies and our daily choices.

When we talk about sustainability, attention is often focused on the energy transition, sustainable mobility or food systems. However, a crucial but often overlooked sector is fashion, responsible for approximately 10% of global greenhouse gas emissions and water consumption of over 90 billion cubic meters per year.

Circular fashion represents a concrete response to this challenge, proposing a model in which materials are kept in the production cycle for as long as possible.

REGENSTECH: TRANSFORMING WASTE INTO A RESOURCE

It is precisely in this direction that Regenstech operates, a startup born from the desire to identify the reference technology capable of transforming all textile and leather waste from the fashion industry, both pre and post-consumer, into new high-quality secondary raw materials. Our mission is clear: to give new life to materials that would otherwise end up in landfill, contributing to a truly circular economy in the fashion sector.

What sets Regenstech apart is the innovative “From Textile to Non Textile” approach, which overcomes the traditional limitations of textile-to-textile recovery. The latter, while representing a valid solution, is only applicable to a minority percentage of products, typically requiring single-material waste. Our proprietary technology, on the other hand, allows us to transform all textile and fashion waste (of vegetal, animal or mixed origin) into new materials with high-quality plastic properties.

This approach is particularly significant because it addresses one of the biggest challenges in textile recycling: the management of mixed fabrics. According to the most recent data, over 70% of textile waste is composed of mixed fibers, which are difficult to separate with traditional technologies. Our innovative process instead allows us to valorize these complex materials, transforming them into new resources.

The data speaks for itself: over 12.6 million tons of textile waste are generated every year in the European Union, but less than 30% is actually recycled. Most of it ends up in landfill or is incinerated, with serious environmental consequences.

In Italy, the situation is no better: we produce around 1.7 million tons of textile waste per year, of which only 15% is sent for effective recovery. This is because traditional recycling systems are not able to effectively manage mixed fabrics, which represent over two-thirds of the total.

OUR CONCRETE COMMITMENT

At Regenstech, we firmly believe that technology is the key to transforming textile waste into new resources. Our technology allows us to recover all textile materials without the need for preliminary sorting. It is not just about recycling, but about creating a new paradigm in which waste becomes precious resources for new production cycles.

An approach that allows us to save natural resources, reduce CO₂ emissions and make a concrete contribution to postponing Overshoot Day in the years to come